TR Self Clinch Pin installation

- Punch or drill the mounting hole. Do not deburr the hole or perform any other secondary operations

- Place fastener into anvil recess then place sheet over the fastener spigot

- Apply squeezing force, ensuring that the punch and anvil surfaces are parallel, until the retainer shoulder makes contact with the face of the sheet

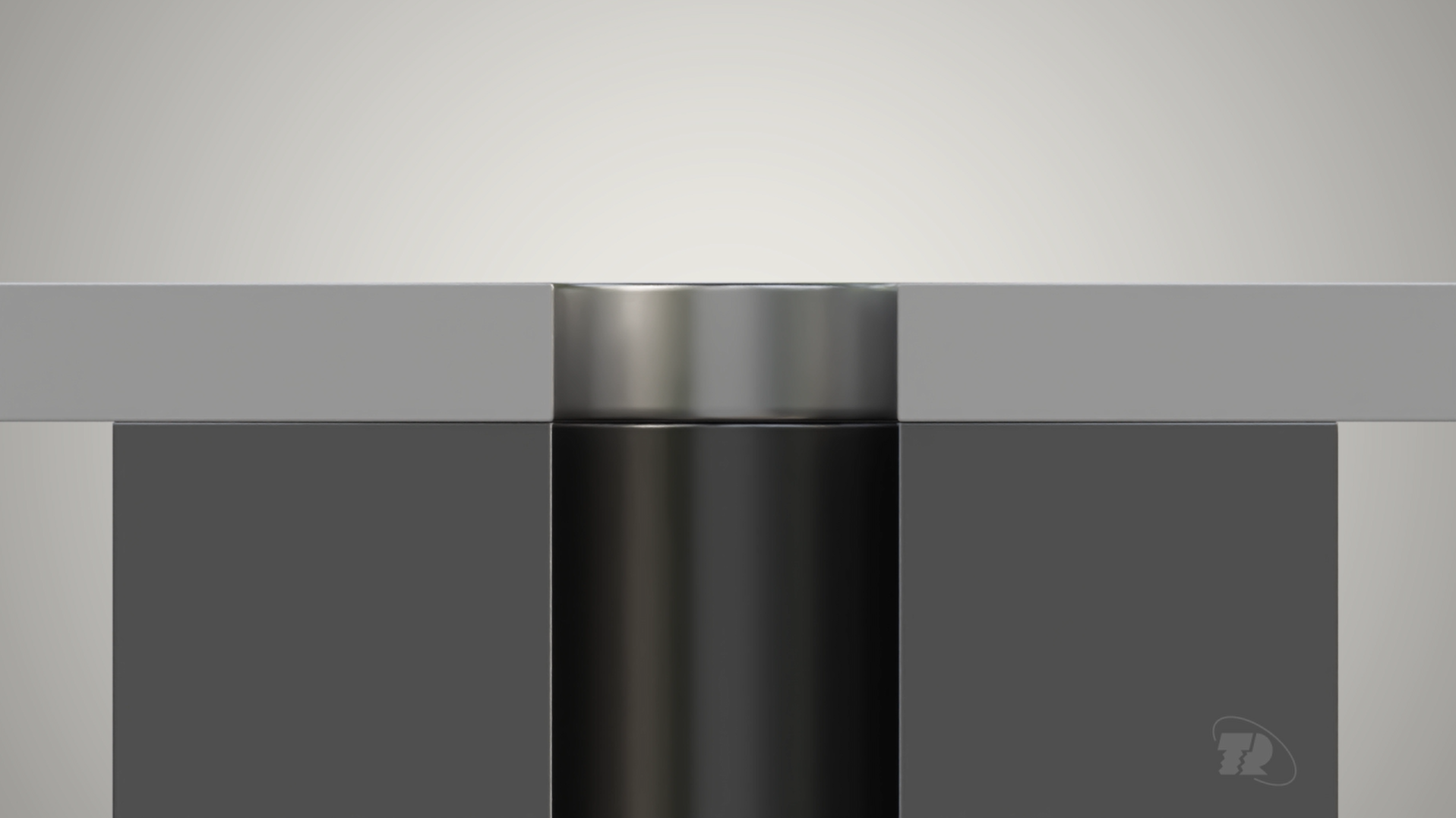

1 Step 1

Select the appropriate hole size from the table below for the pin size required. Punch the hole diameter into the sheet and place on top of the appropriate anvil.

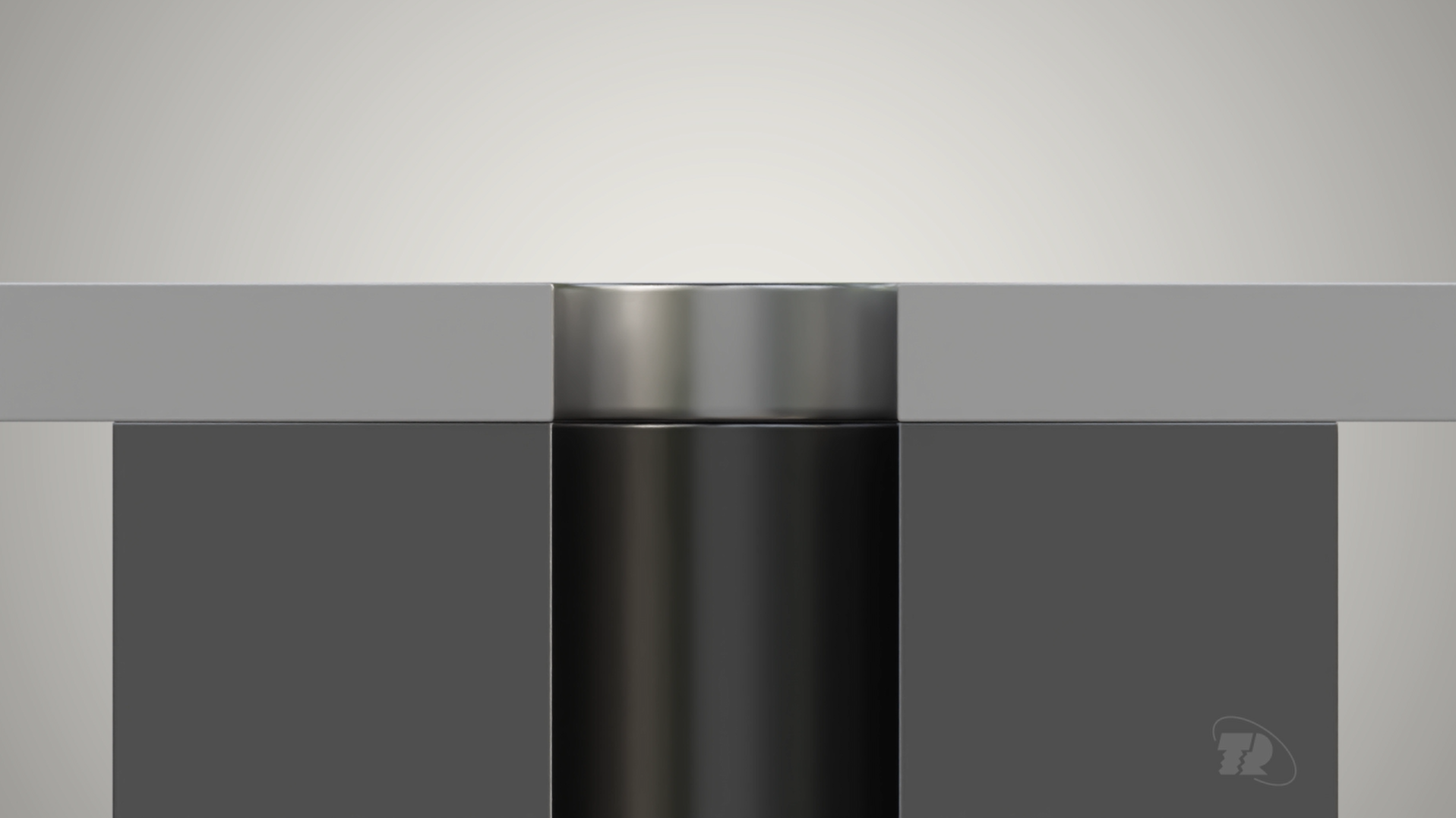

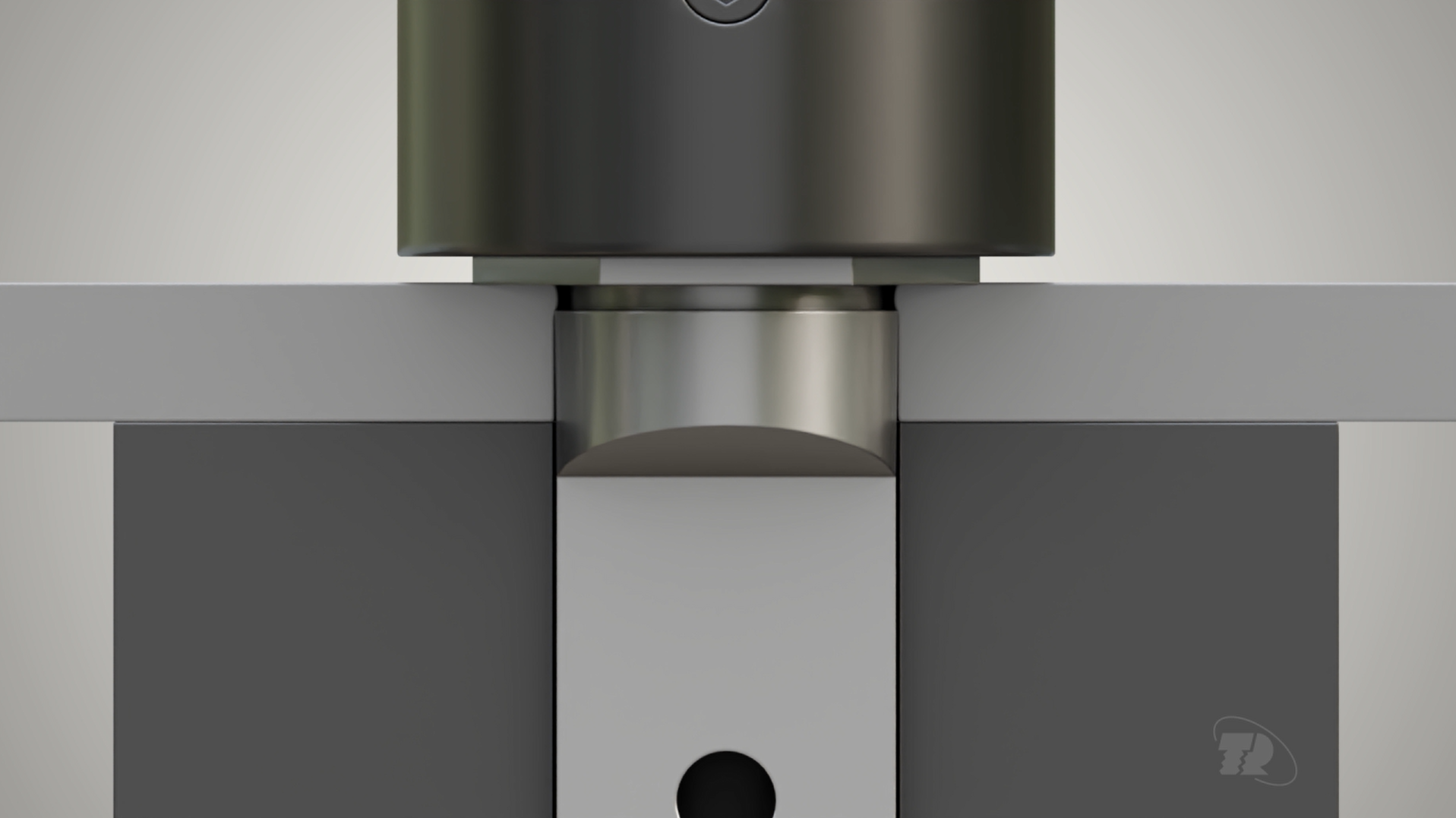

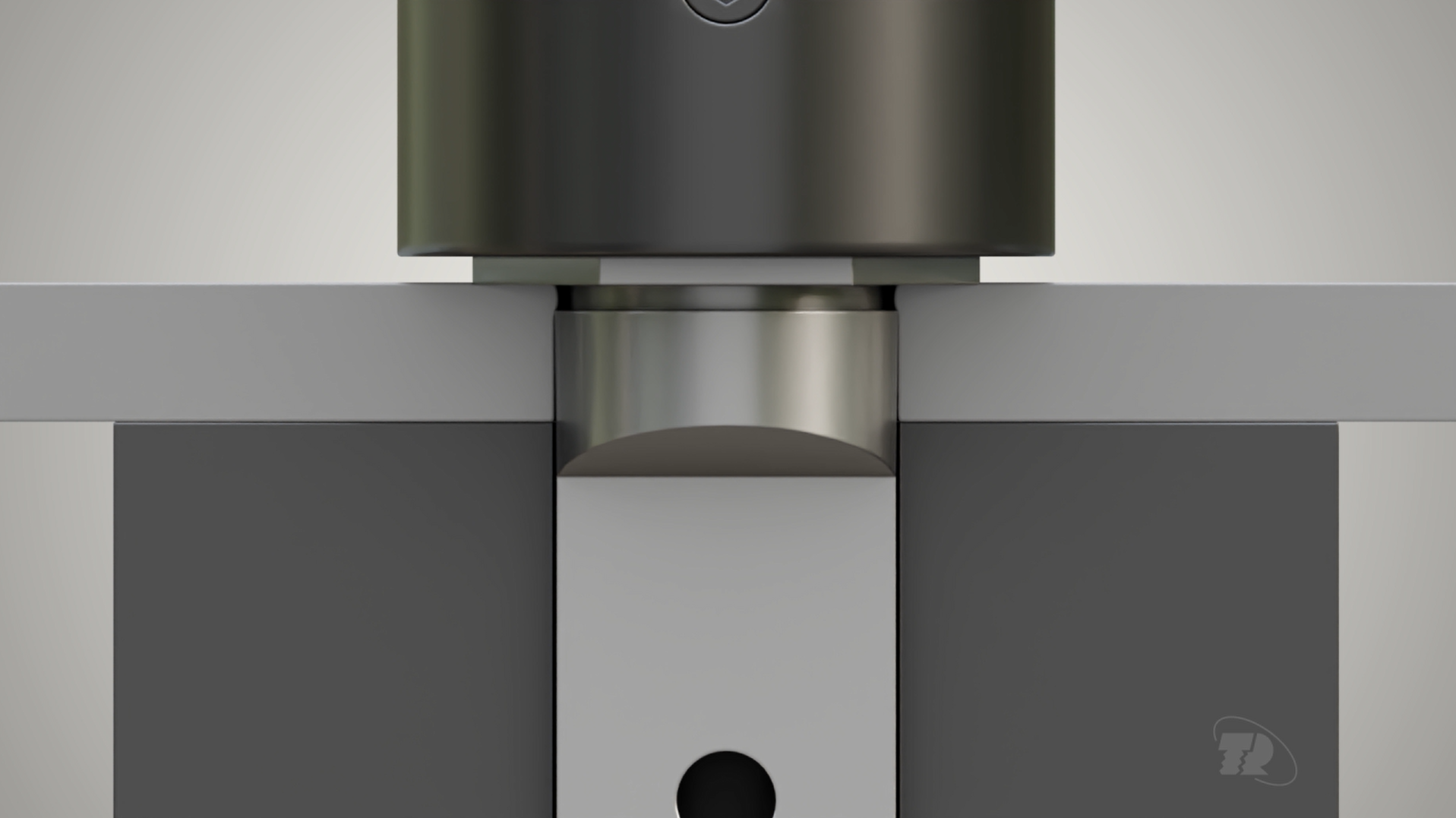

2 Step 2

Place the pin so that the head serrations rest on the parent material. Ensure both plate and stud are aligned along the same axis. If not, the joint will be imperfect and mating threads will misalign.

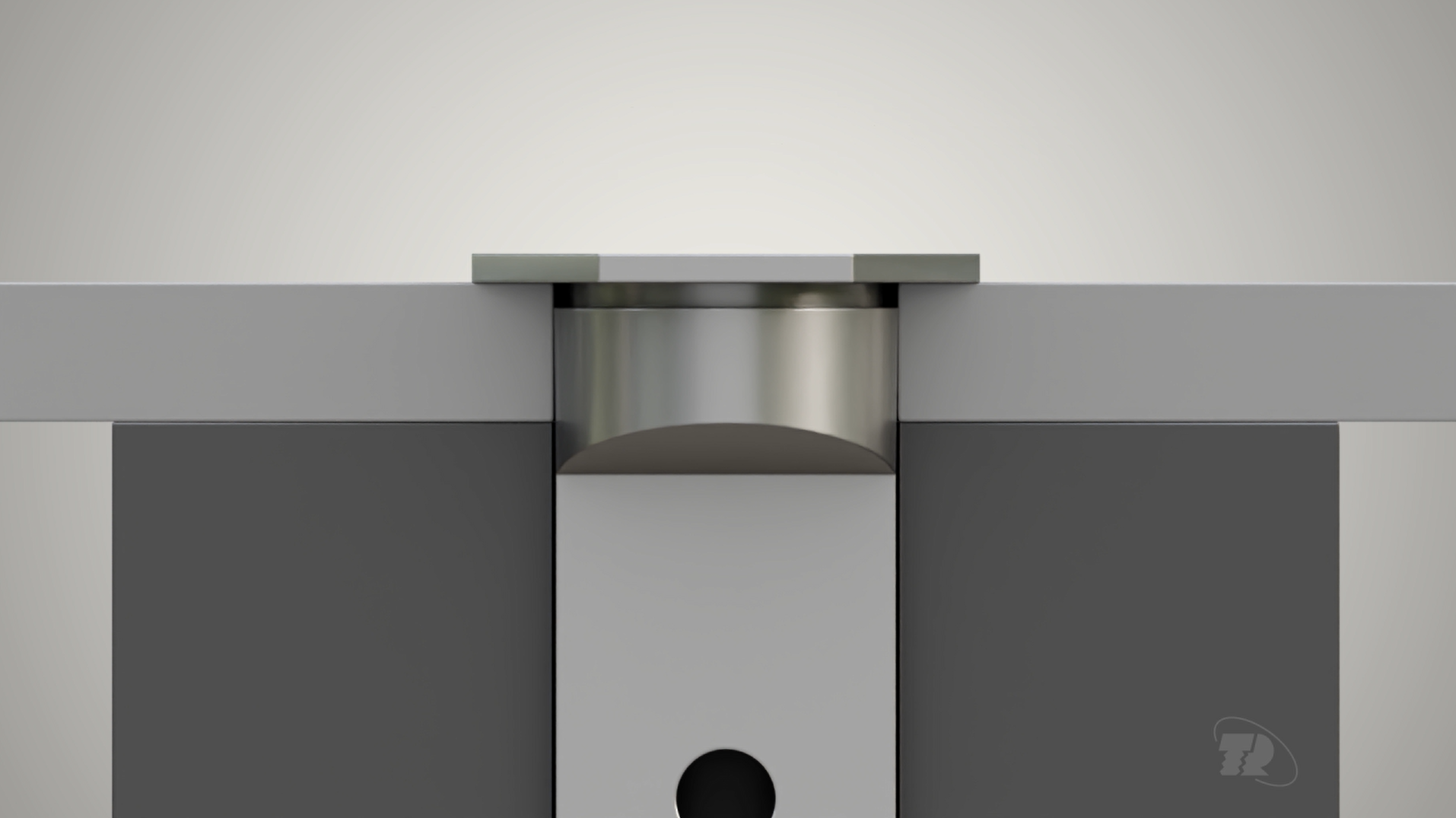

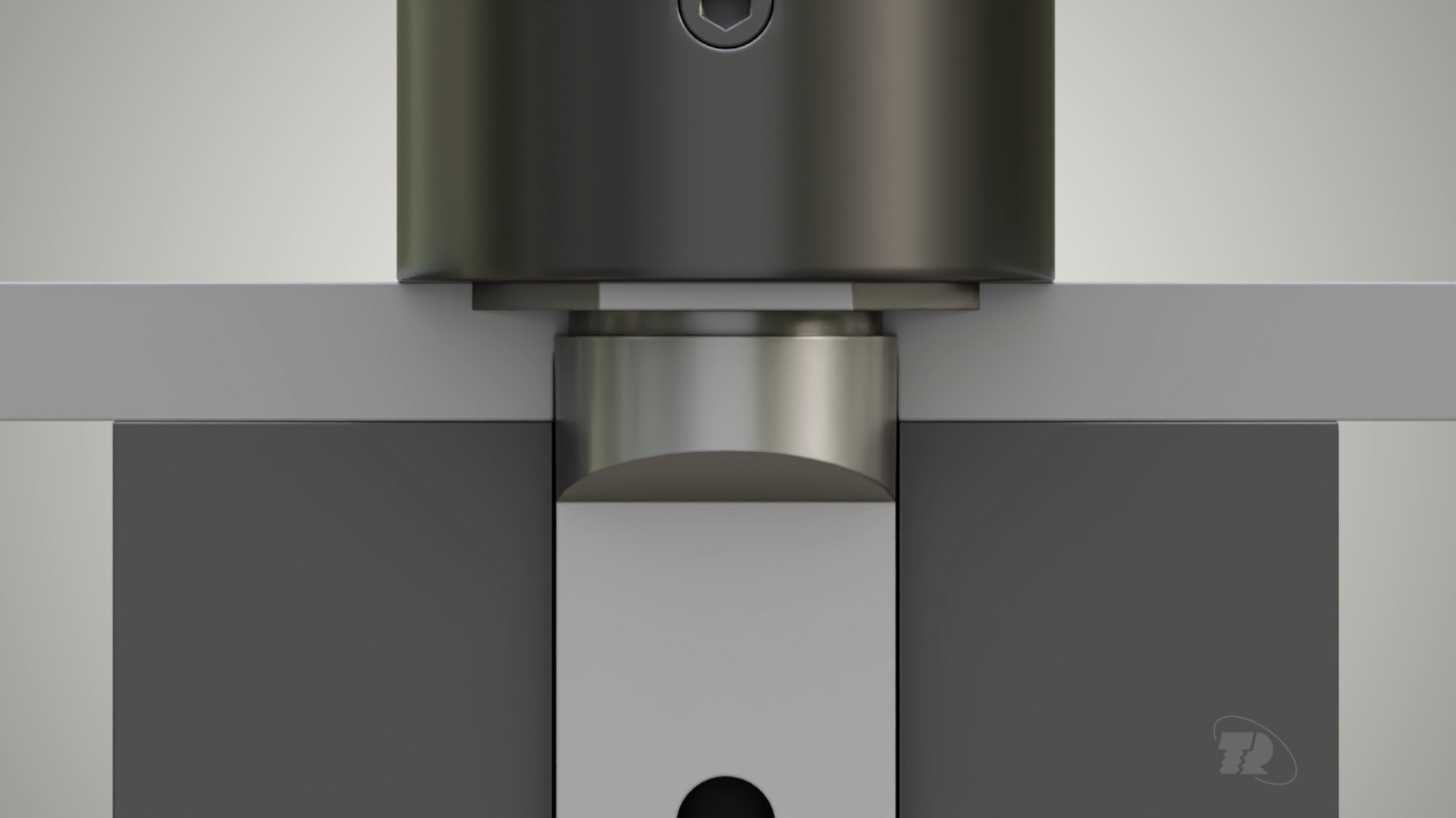

3 Step 3

Using a flat faced punch, apply only sufficient pressure to ‘squeeze’ the pin head and its under head tooth features into the parent sheet.

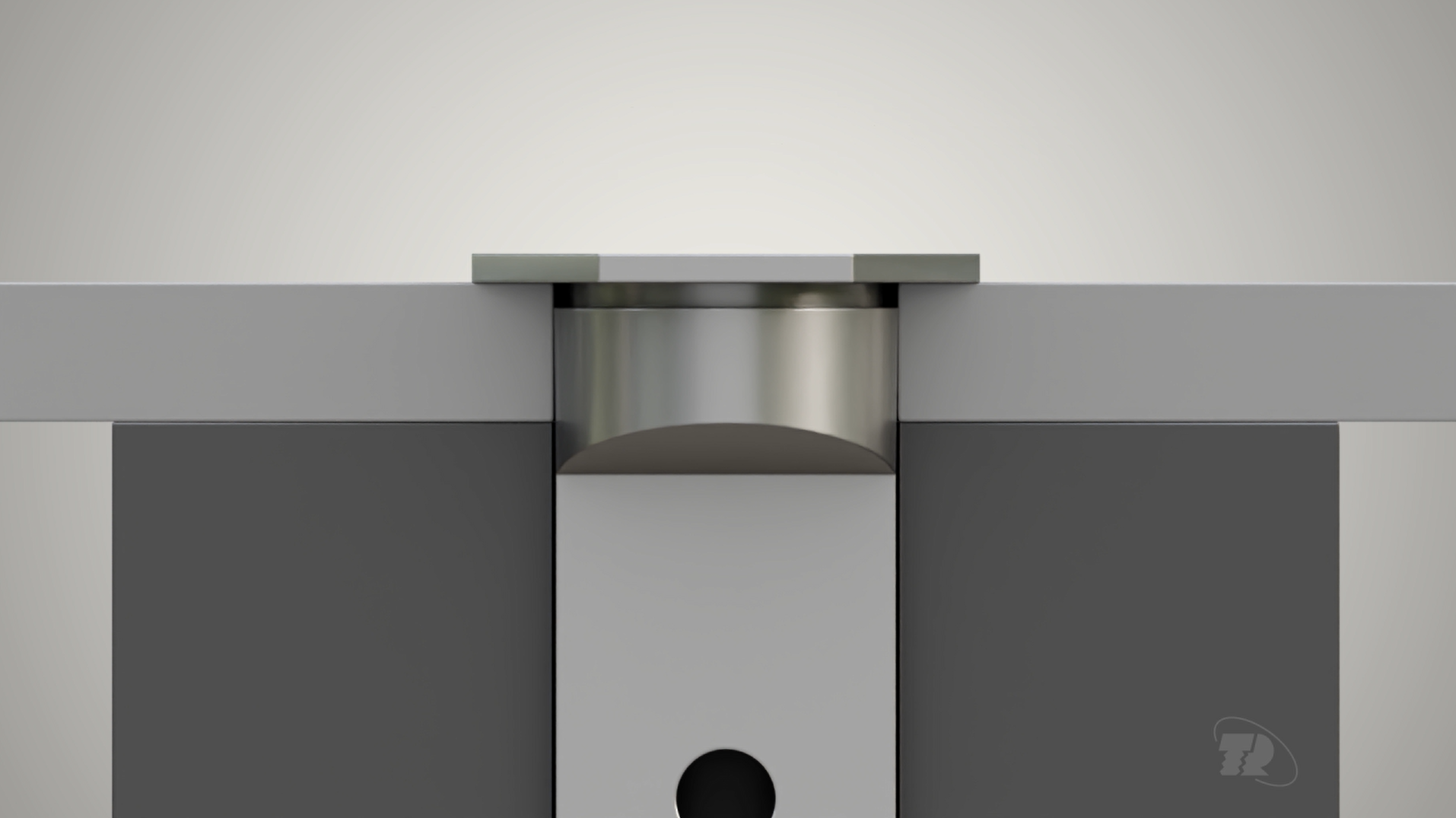

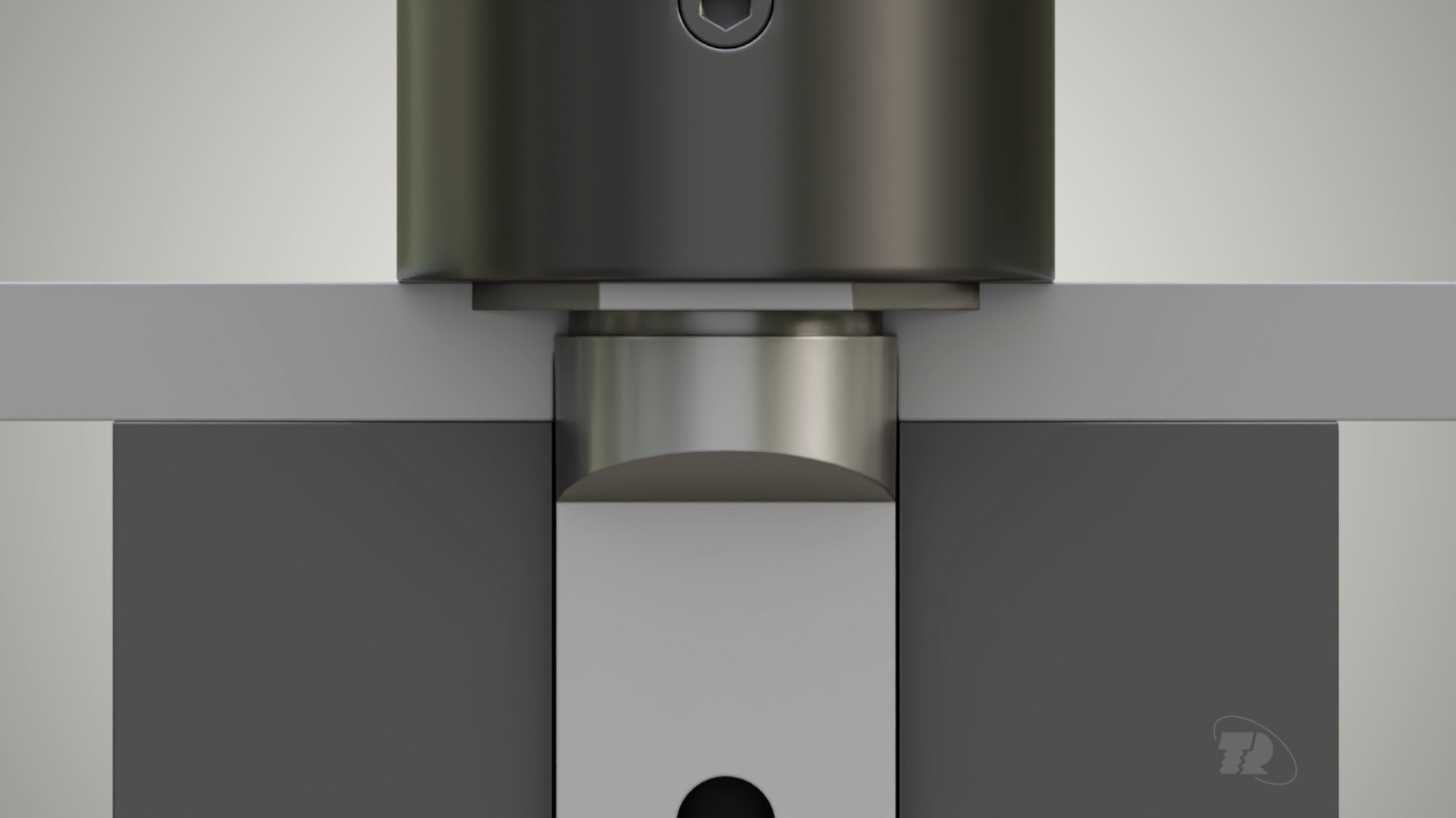

4 Step 4

The tooth locking feature if properly installed will provide torsional (rotational) resistance. After installation the spigot joint should be flush with the sheet.

Installation animation

Hole sizes - metric (mm)

| Pin diameter +/- 0.05 | Min. sheet thickness | Hole size in sheet + 0.08 | Min. distance hole C/L to edge |

|---|---|---|---|

| 3mm | 1 | 3.5 | 6.4 |

| 4mm | 1 | 4.5 | 7.1 |

| 5mm | 1 | 5.5 | 7.6 |

| 6mm | 1 | 6.5 | 7.9 |

Hole sizes - inches

| Pin diameter -0.002 | Min. sheet thickness | Hole size in sheet + 0.08 | Min. distance hole C/L to edge |

|---|---|---|---|

| 0.125 | 0.040 | 0.145 | 0.255 |

| 0.187 | 0.040 | 0.205 | 0.285 |

| 0.250 | 0.040 | 0.273 | 0.315 |

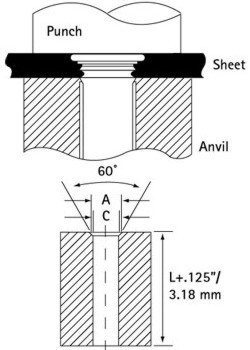

Tooling

| Sheet thickness: up to 1.7mm for 3mm and 4mm diameter, up to 1.8mm for 5mm diameter, up to 1.9mm for 6mm diameter | |||

|---|---|---|---|

|

Pin Dia. | A mm 0.05 | C mm 0.05 |

| 3mm | 3.88 | 3.11 | |

| 4mm | 4.88 | 4.11 | |

| 5mm | 5.89 | 5.13 | |

| 6mm | 6.89 | 6.12 | |

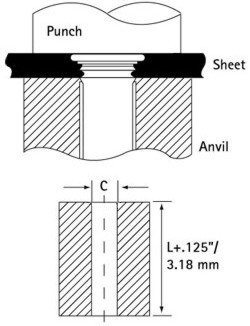

| Sheet Thickness: over 1.7mm for 3mm and 4mm diameter, over 1.8mm for 5mm diameter, over 1.9mm for 6mm diameter | |||

|---|---|---|---|

|

Pin Dia. | A mm 0.05 | C mm 0.05 |

| 3mm | N/A | 3.11 | |

| 4mm | N/A | 4.11 | |

| 5mm | N/A | 5.13 | |

| 6mm | N/A | 6.12 | |