TR IN INDUSTRY

Automotive

Fasteners & components for light and heavy vehicles

This sector represents our largest and most global revenue base, with TR holding strong positions with many of the world’s leading automotive Tier 1 system suppliers

We see continued growth potential in this sector and recognize the need to balance growth with risk-managed contractual relationships, focusing on technologies and systems for future vehicle platforms

Legislation and public demand are driving the acceleration of zero or ultra low emission vehicles, resulting in rapid design changes and new fastening requirements. The speed of deployment is increasing, and there is a heightened awareness of new environmental legislation. We support the heavy vehicle sector with a range of products and services tailored to their diverse needs, keeping these regulations in mind

TR is capable of supplying most fastenings within a vehicle. Initially focused on vehicle interiors, our range has expanded significantly to cover most of the Bill of Material (BoM). With the rapid acceleration of electric vehicles and battery technology, global opportunities are emerging as companies work towards the zero-emission vehicle targets set for 2030.

The scale of change brings newer technical challenges, such as heat and cable management, conductivity, and electrostatic finishes. These demands are often fast-paced and required globally on modular platforms, particularly evident in battery housings.

Where we supply

Engineering and technical support

Our engineering and technical support is deployed early in the design cycle to meet these needs. The demands of the circular economy and product recyclability are strong considerations in any new design. Correct fastener design and selection are key to the success of modularity and the design life of skateboard platforms.

Strategically selecting serviceable fasteners for modules or elements that will require maintenance or future updates helps meet eco-design criteria. This retains maximum value at the end of a vehicle’s life and contributes to extended producer responsibility regulations, aiding the final responsibility for the disposal of manufactured products.

Innovative design and service solutions

Speed to market and the introduction of innovative design and service solutions that create value throughout the supply chain underline TR's unique selling proposition (USP). Truck, bus, and van designs are undergoing radical changes with steep learning curves as vehicle ergonomics evolve.

New start-up companies with tech backgrounds have a different mindset compared to conventional manufacturers. This shift is driven by the increased demand for ‘last mile deliveries’ supporting online shopping, leading to the development of electric vehicles (EV) manufactured on common skateboard platforms. This necessitates a fast-to-market supply chain and early design involvement, providing solutions for the latest designs. Considerations also include accommodating the weight of electric batteries and housing units, which are important for environmental considerations in inner-city deliveries.

Related products

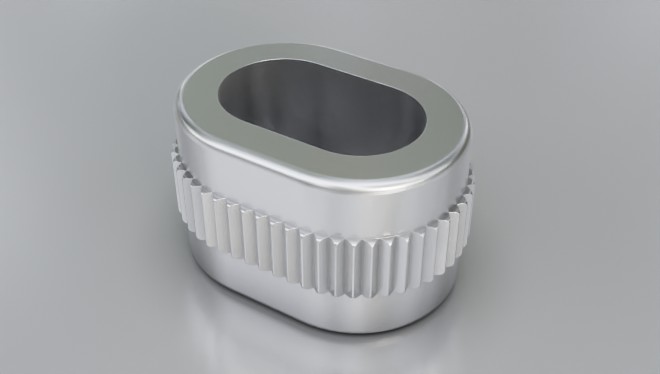

COMPRESSION LIMITERS Symmetrical, Flanged, Oval, Round

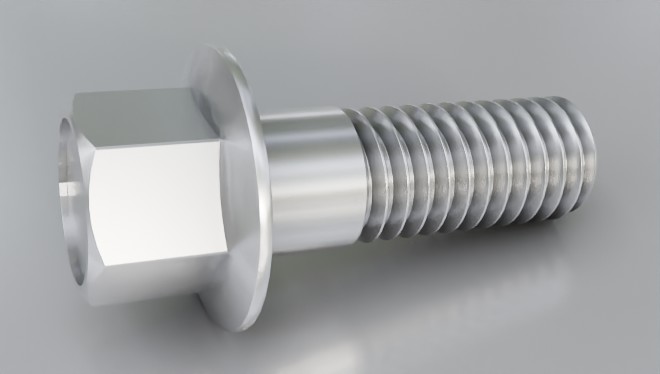

COMPRESSION LIMITERS Symmetrical, Flanged, Oval, Round  FLANGE BOLTS Flange Bolts

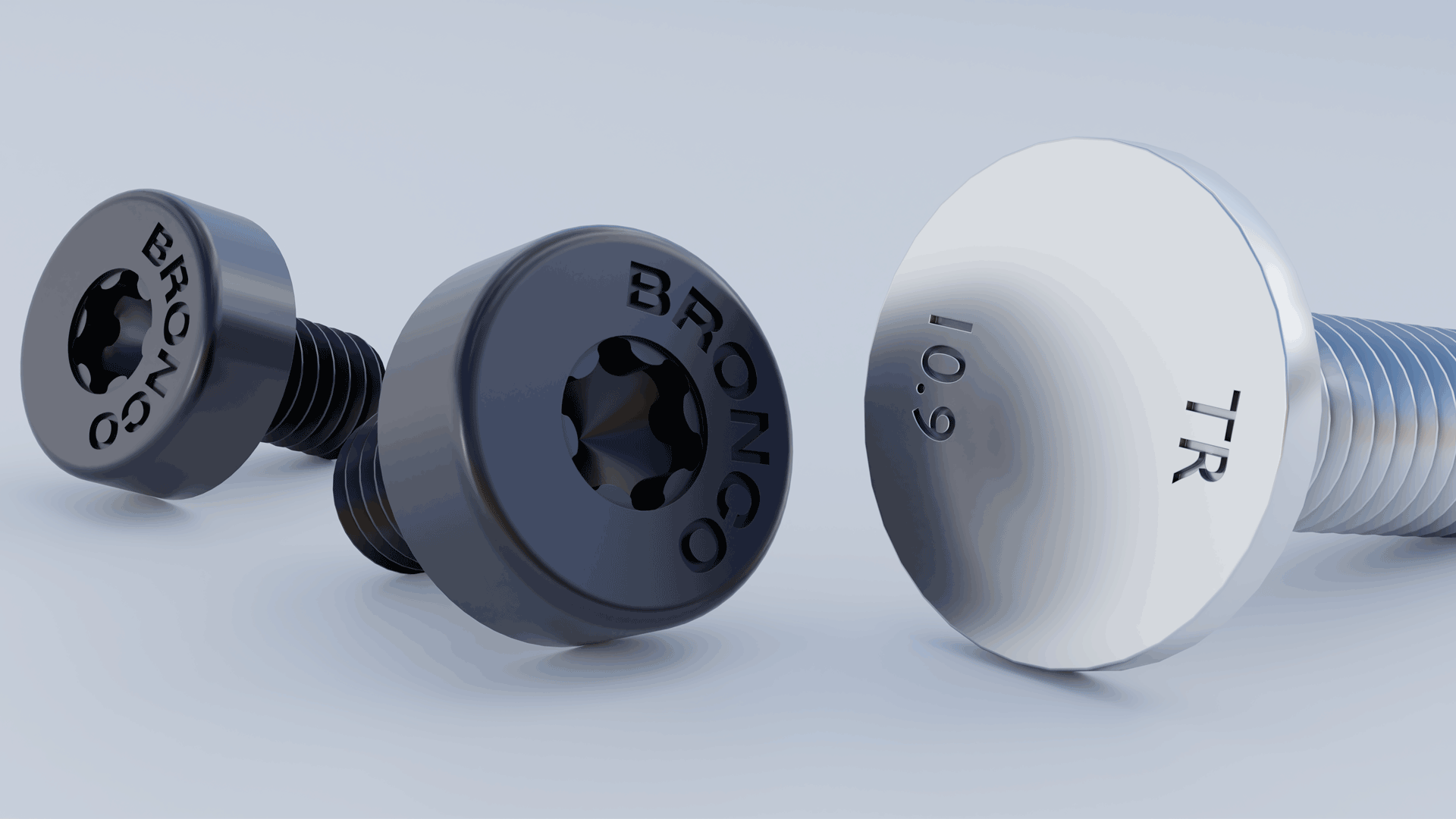

FLANGE BOLTS Flange Bolts  SPECIALS Specials

SPECIALS Specials  WELD PRODUCTS Weld Nuts, Weld Bolts

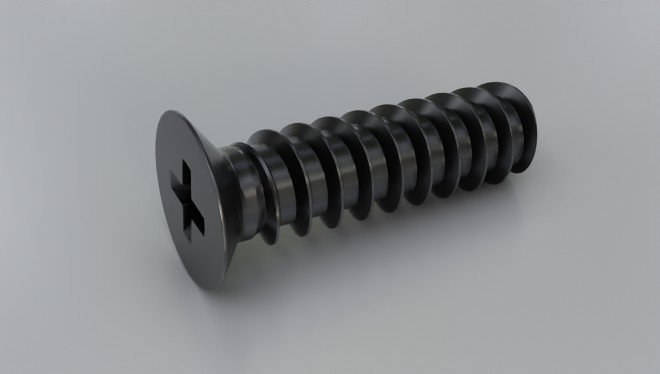

WELD PRODUCTS Weld Nuts, Weld Bolts  SCREWS FOR PLASTIC Plas-Tech® 30, Plas-Fix® 45, Plas-Fix® 60, Thread Cutting Type BT, Thread Cutting Type Y, High-Low Thread, JCIS P-Type, JCIS B-Type

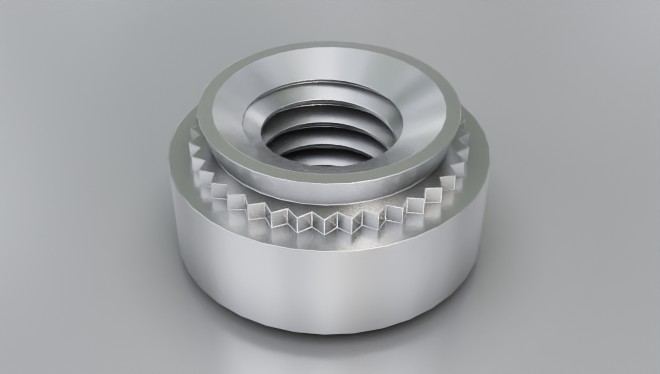

SCREWS FOR PLASTIC Plas-Tech® 30, Plas-Fix® 45, Plas-Fix® 60, Thread Cutting Type BT, Thread Cutting Type Y, High-Low Thread, JCIS P-Type, JCIS B-Type  SELF CLINCH FASTENERS Studs, Nuts, Standoffs, Panel Fasteners, Flush Head Pins, Terminal Pins, Cable Tie Mounts

SELF CLINCH FASTENERS Studs, Nuts, Standoffs, Panel Fasteners, Flush Head Pins, Terminal Pins, Cable Tie Mounts  STAINLESS PRODUCTS Stainless Products

STAINLESS PRODUCTS Stainless Products  CLIPS Clips

CLIPS Clips  PLASTIC & RUBBER HARDWARE Circuit Board Hardware, Cable Management, Rivets and Panel Fasteners, Machine Screws, Nuts, Washers, Bumpers, Masking Caps & Plugs

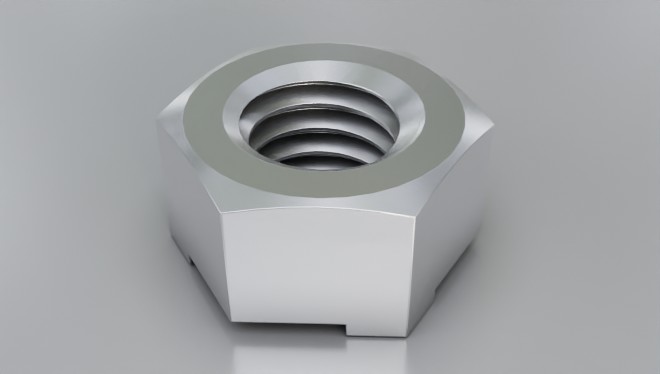

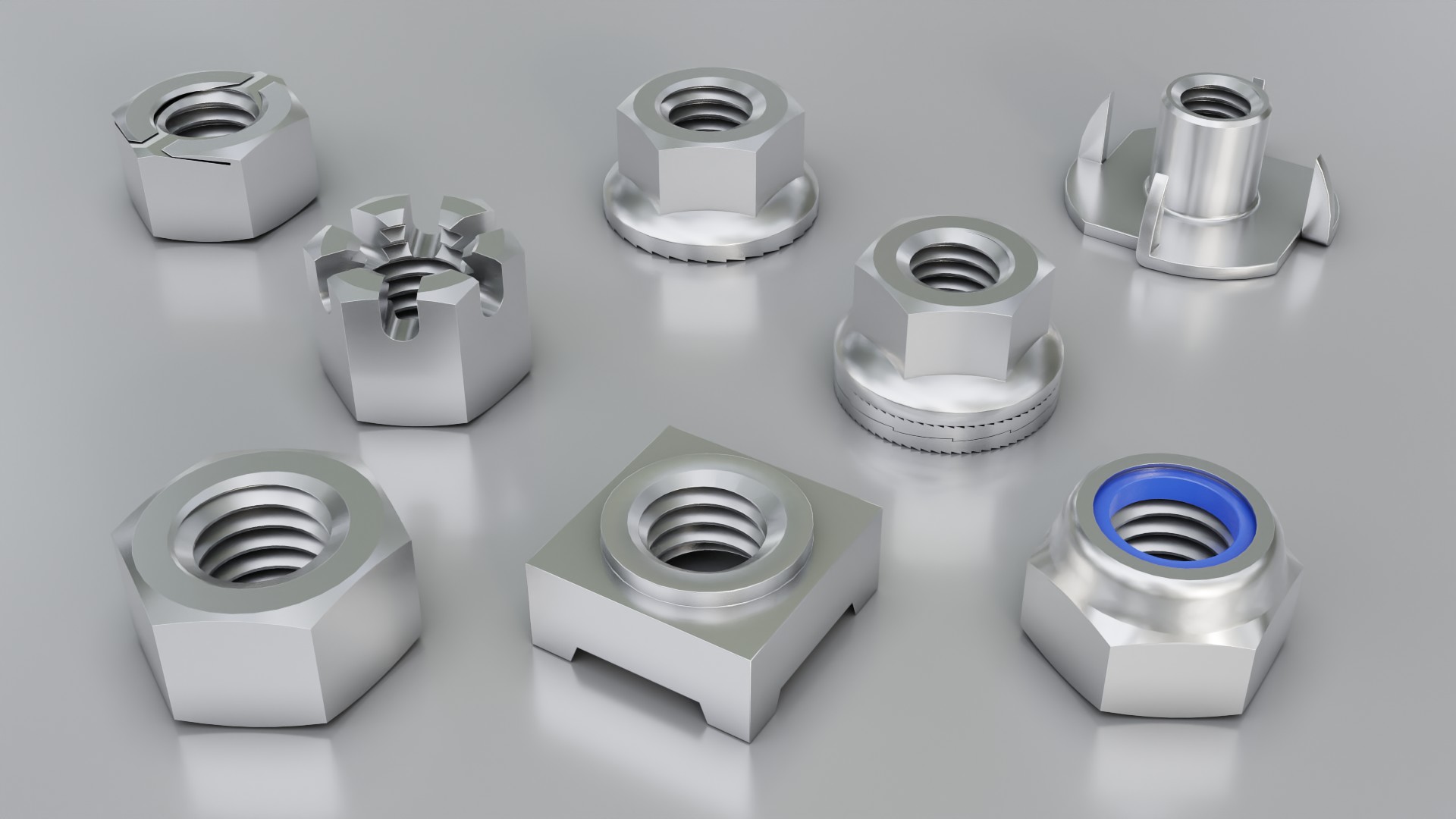

PLASTIC & RUBBER HARDWARE Circuit Board Hardware, Cable Management, Rivets and Panel Fasteners, Machine Screws, Nuts, Washers, Bumpers, Masking Caps & Plugs  NUTS Standard Hexagon, Standard Flange, Nylon Insert, All Metal Self Locking, Weld, Cap and more

NUTS Standard Hexagon, Standard Flange, Nylon Insert, All Metal Self Locking, Weld, Cap and more  THREADFORMING SCREWS FOR METAL Tap-Fix DIN7500, JCIS S-Type

THREADFORMING SCREWS FOR METAL Tap-Fix DIN7500, JCIS S-Type  CABLE GLANDS HUMMEL Standard Cable Glands, HUMMEL Flex Cable Glands, HUMMEL Mini Cable Glands, Generic Standard Cable Glands, Generic Mini Cable Glands, Accessories

CABLE GLANDS HUMMEL Standard Cable Glands, HUMMEL Flex Cable Glands, HUMMEL Mini Cable Glands, Generic Standard Cable Glands, Generic Mini Cable Glands, Accessories Services we offer

Contact us

Literature download

View and download all of our brochures and product information using the link below.

Not found what you're looking for?

Complete the form below and one of our team will get back to you:

* is a mandatory field