Tap-Fix® Screws - for aluminium or zinc die casting and steel and aluminium sheet materials

This article provides Tap-Fix® hole size recommendations for metals using two common process scenarios; die cast and all ductile sheet materials.

Tap-fix® screws are thread rolling screws with a trilobular shaped body that reduces friction during threadforming in the parent material. They have been designed to provide consistent torque performance, lower end load and lower thread forming torque.

Industry common suggested thread engagement guidelines:

- Powdered Metal or Cast Iron 50 - 65%

- Colled Rolled Steel 65 - 70%

- Aluminium 70 - 80%

- Thin Sheet Metals 80 - 95%

|

The minimum length of thread engagement should be equal to twice the diameter of the screw. The hole diameter should provide for 65% to 75% thread engagement to ensure optimum assembly performance. |

|---|

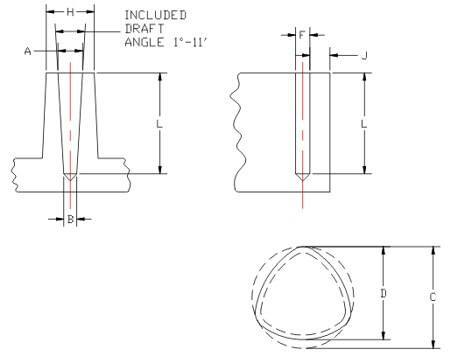

Table 1: suggested hole sizes for aluminium or zinc die casting

| Metric sizes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Screw size | Hole diameter as cast std taper | F hole dia. as drilled | L length of thread eng't | H boss dia. min. | J distance to edge | |||

| Top A | Bottom B | |||||||

| Min | Max | Min | Max | |||||

| M2 x 0.40 | 1.91 | 1.83 | 1.81 | 1.73 | 1.81 | 4 | 3.32 | 1 |

| M2.5 x 0.45 | 2.39 | 2.31 | 2.28 | 2.2 | 2.28 | 5 | 4.15 | 1.2 |

| M3 x 0.50 | 2.9 | 2.82 | 2.76 | 2.68 | 2.76 | 6 | 4.98 | 1.3 |

| M3.5 x 0.6 | 3.31 | 3.23 | 3.21 | 3.13 | 3.21 | 7 | 5.81 | 1.6 |

| M4 x 0.7 | 3.82 | 3.74 | 3.64 | 3.56 | 3.64 | 8 | 6.64 | 1.8 |

| M4.5 x 0.75 | 4.31 | 4.23 | 4.11 | 4.03 | 4.11 | 9 | 7.47 | 2 |

| M5 x 0.8 | 4.8 | 4.72 | 4.58 | 4.5 | 4.58 | 10 | 8.3 | 2.1 |

| M6 x 1.0 | 5.74 | 5.66 | 5.48 | 5.4 | 5.48 | 12 | 9.96 | 2.6 |

| M6.3 x 1.0 | 6.05 | 5.97 | 5.78 | 5.7 | 5.78 | 13 | 10.46 | 2.6 |

| M7 x 1.0 | 6.78 | 6.7 | 6.48 | 6.4 | 6.48 | 14 | 11.62 | 2.6 |

| M8 x 1.25 | 7.69 | 7.61 | 7.35 | 7.27 | 7.35 | 16 | 13.28 | 3.3 |

| M10 x 1.5 | 9.64 | 9.56 | 9.22 | 9.14 | 9.22 | 20 | 16.6 | 3.9 |

| M12 x 1.75 | 11.59 | 11.51 | 11.09 | 11.01 | 11.09 | 24 | 19.92 | 4.6 |

| Inch sizes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Screw size | Hole diameter as cast std taper | F hole dia. as drilled | L length of thread eng't | H boss dia. min. | J distance to edge | |||

| Top A | Bottom B | |||||||

| Min | Max | Min | Max | |||||

| 2-56 | 0.081 | 0.078 | 0.077 | 0.074 | 0.077 | 0.172 | 0.197 | 0.046 |

| 3-48 | 0.093 | 0.09 | 0.088 | 0.085 | 0.088 | 0.198 | 0.208 | 0.054 |

| 4-40 | 0.105 | 0.102 | 0.099 | 0.096 | 0.099 | 0.224 | 0.22 | 0.065 |

| 5-40 | 0.118 | 0.115 | 0.112 | 0.109 | 0.112 | 0.25 | 0.232 | 0.065 |

| 6-32 | 0.128 | 0.125 | 0.122 | 0.119 | 0.122 | 0.276 | 0.242 | 0.081 |

| 8-32 | 0.155 | 0.152 | 0.148 | 0.145 | 0.148 | 0.328 | 0.272 | 0.081 |

| 10-24 | 0.177 | 0.174 | 0.168 | 0.165 | 0.168 | 0.38 | 0.315 | 0.108 |

| 10-32 | 0.182 | 0.179 | 0.174 | 0.171 | 0.174 | 0.38 | 0.315 | 0.081 |

| 12-24 | 0.203 | 0.2 | 0.194 | 0.191 | 0.194 | 0.432 | 0.359 | 0.108 |

| 1/4-20 | 0.235 | 0.232 | 0.224 | 0.221 | 0.224 | 0.5 | 0.415 | 0.13 |

| 5/16-18 | 0.297 | 0.294 | 0.284 | 0.281 | 0.284 | 0.625 | 0.519 | 0.144 |

| 3/8-16 | 0.359 | 0.356 | 0.343 | 0.34 | 0.343 | 0.75 | 0.623 | 0.162 |

| 7/16-14 | 0.419 | 0.416 | 0.4 | 0.397 | 0.4 | 0.875 | 0.726 | 0.186 |

| 1/2-13 | 0.481 | 0.478 | 0.46 | 0.457 | 0.46 | 1 | 0.83 | 0.2 |

Table 2: suggested pilot hole sizes for steel & aluminium sheet materials 0.5mm through to 12mm

The following table illustrates suggested pilot holes for steel (rockwell B 55-75) and aluminium (rockwell B 40-70) will give satisfactory results in many cases.

| Suggested pilot hole sizes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Steel | Aluminium | Steel | Aluminium | Steel | Aluminium | Steel | Aluminium | Steel | Aluminium |

| Thickness | 0.5 - 2mm | 1.5 - 3.5mm | 3 - 6.5mm | 6 - 8mm | 8 - 12mm | |||||

| M2 x 0.4 | 1.75 | 1.7 | 1.8 | 1.75 | - | - | - | - | - | - |

| M2.5 x 0.45 | 2.25 | 2.2 | 2.3 | 2.25 | 2.35 | 2.3 | - | - | - | - |

| M3 x 0.5 | 2.7 | 2.6 | 2.75 | 2.7 | 2.8 | 2.75 | - | - | - | - |

| M3.5 x 0.6 | 3.1 | 3.1 | 3.2 | 3.1 | 3.2 | 3.2 | 3.25 | 3.2 | 3.3 | 3.25 |

| M4 x 0.7 | 3.6 | - | 3.7 | 3.6 | 3.75 | 3.7 | 3.75 | 3.7 | 3.8 | 3.75 |

| M5 x 0.8 | - | - | 4.5 | 4.5 | 4.6 | 4.5 | 4.7 | 4.6 | 4.7 | 4.7 |

| M6 x 1.0 | - | - | 5.4 | 5.4 | 5.5 | 5.4 | 5.6 | 5.5 | 5.7 | 5.6 |

| M8 x 1.25 | - | - | 7.3 | 7.3 | 7.4 | 7.3 | 7.5 | 7.4 | 7.6 | 7.5 |

| M10 x 1.5 | - | - | - | - | 9.25 | 9.2 | 9.3 | 9.25 | 9.4 | 9.3 |

| M12 x 1.75 | - | - | - | - | - | - | 11.2 | 11.1 | 11.3 | 11.2 |