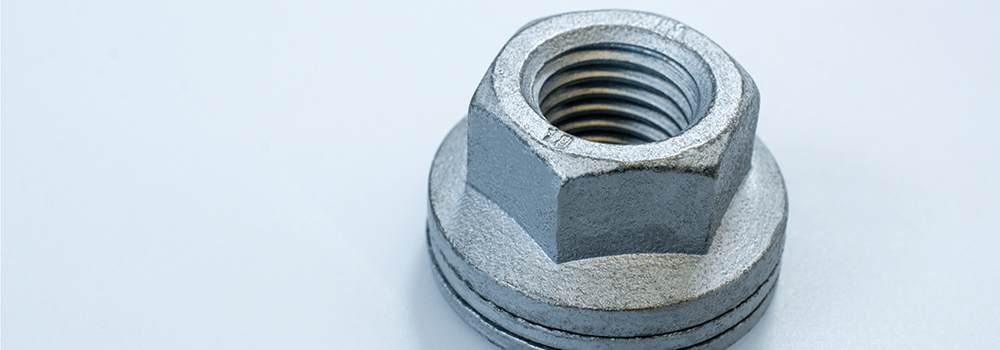

Wedge Lock Nuts

The Wedge Lock Nut provides a high-quality, user-friendly bolt securing system for the most demanding of applications and is ideal for repeated use. The captive and rotary combination of the nut and the original Wedge Lock Washers makes securing your bolted joints more efficient, effective, and easier even under the most extreme vibrations and dynamic loads.

Design of the Wedge Lock Nut

The Wedge Lock Nut is supplied preassembled. The nut and the Wedge Lock Washers are combined in a captive and rotary way, ensuring the Wedge Lock Washers and the nut are fixed permanently in the correct position with the wedge lock washers securing your bolted joint using the proven principle without loss of quality or function.

Advantages

- The one-piece design eliminates the risk of misuse

- Minimized risk of operating and production breakdowns caused by faulty bolted connections

- Easy handling especially in hard to reach locations

- Fixed permanently in the correct position

- Reduction of assembly time and effort

- Reduced complexity of the component due to less individual parts

- Easy, safe, and fast installation even for non-specialist users

- Can be re-used without any reduction in function or quality

Technical specifications

|

1. Pre-assembled locking system

|

|

2. Difference in hardness: Nut > Material

|

|

3. Difference in angles

|

|

4. Difference in friction

|

|

5. Difference in preload

|