The vital role played by Enclosure and Locking Hardware within the rail sector cannot be overemphasised when it comes to the protection and continuity of equipment, signalling and controls, as well as the Locking Systems used on board trains

Not only does this hardware ensure that such essential equipment and systems – from trackside cabinets to signalling panels – are kept secure at all times; it also shields them from hazardous environments, corrosion and extreme weather.

Rail: the digital revolution

Against this backdrop comes a new era of digitalisation, which is set to transform the rail industry.

With massive investment already made in such projects as the £7 billion Government sponsored Thames Link and 117 kilometre Crossrail (excessive and extremely costly delays not withstanding), the challenge the industry faces is that this massive investment must be matched by the hardware supplied to support these initiatives, in terms of their sophistication, reliability and low cost of maintenance.

Digitalisation may well be the proving ground for a new way of interacting with suppliers, aptly exemplified by the first implementation of digital interlocking technology on a UK passenger-carrying line in June this year, which involved new technologies, software systems and working methods being specifically developed, tested and coming together at the same time. The control system covers a short section of line between Fulwell and Strawberry Hill in southwest London and forms the first stage of Network Rail’s Feltham area re-signalling project.

Undoubtedly, digital transformation in the railway sector over recent years has been accelerated by the emergence of the Internet of Things (IoT), cloud computing, Big Data Analytics (BDA), automation and robotics, as well as Industry 4, and, more recently, Railway 4.0 and Digital Railway. They have become the gauntlet that digitalisation has thrown down, reflecting the technological advancements fast becoming accessible to the rail sector – the latest embodiment of a long tradition of development and change in the industry.

Enclosure Hardware: safe and secure

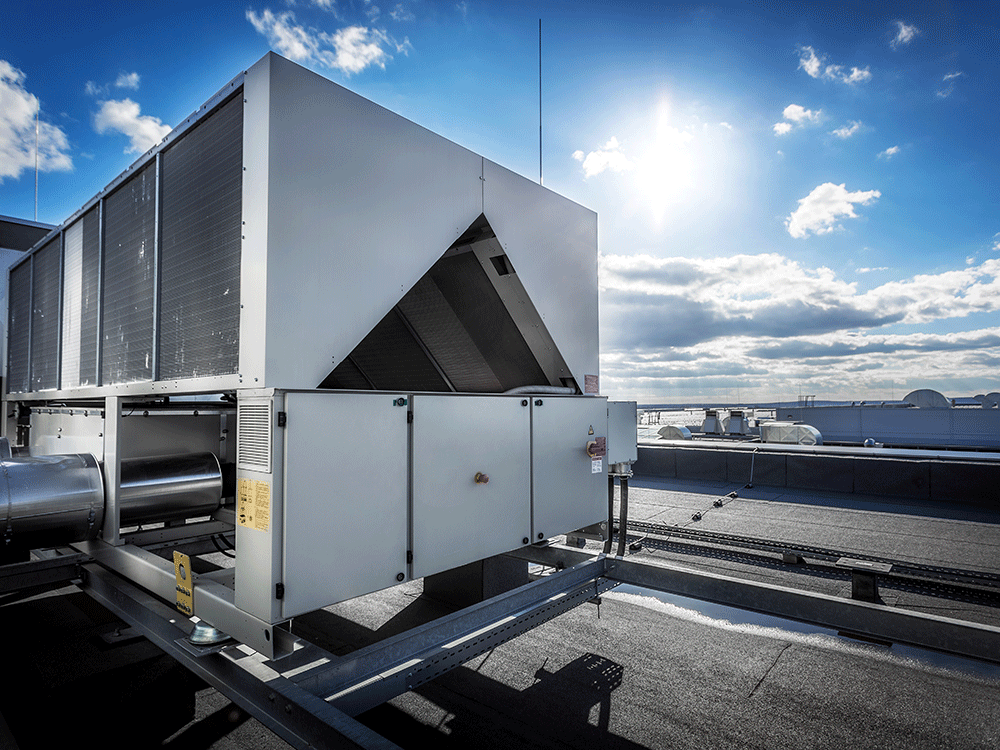

The role played by enclosures in the sector largely remains the same: to house and protect crucial equipment.

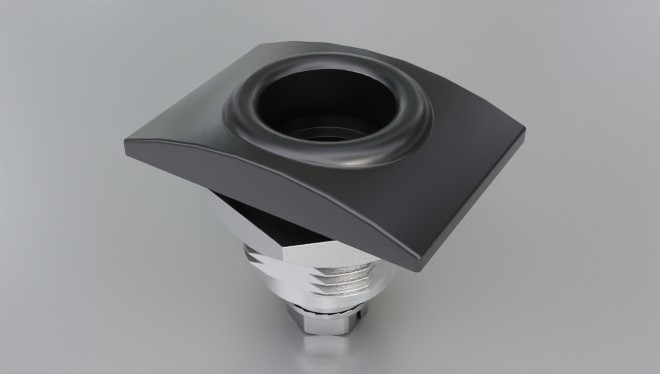

However, as the technology changes and the equipment becomes arguable more sophisticated and complex, the need to ensure the enclosures are robust and secure becomes greater.

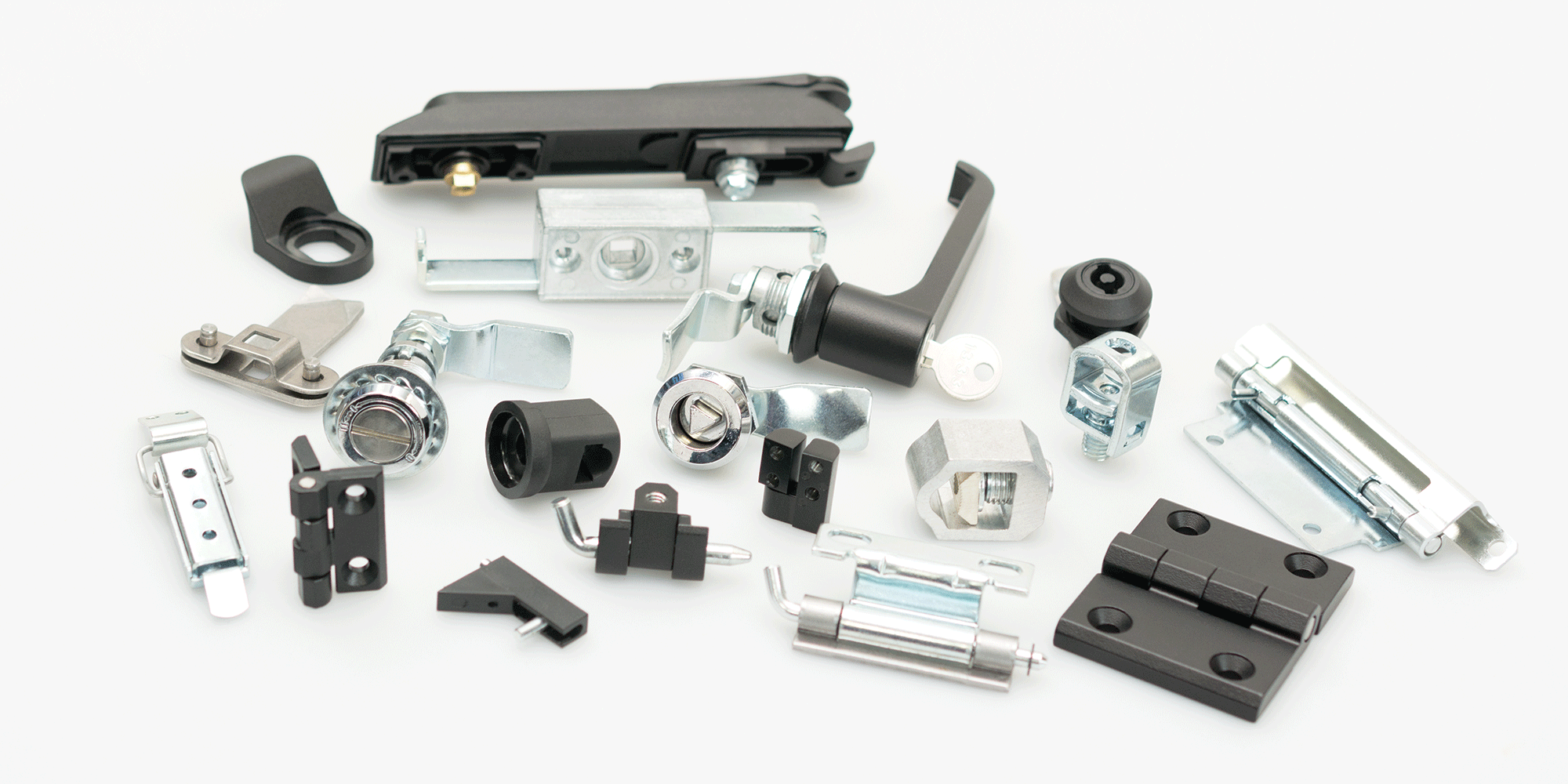

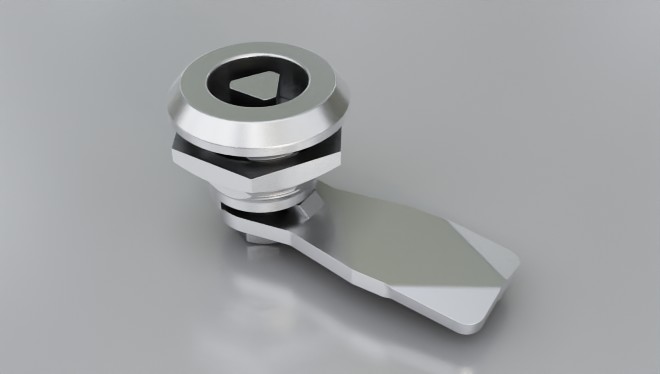

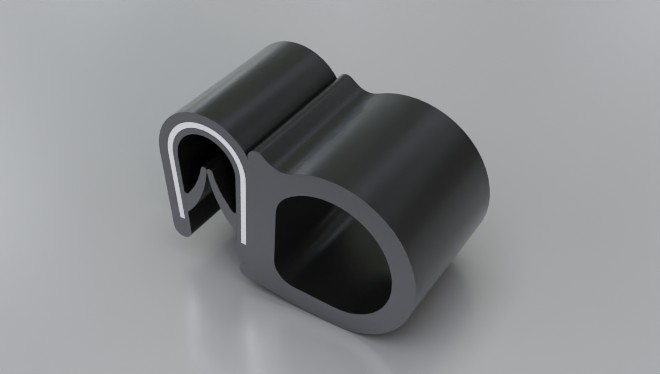

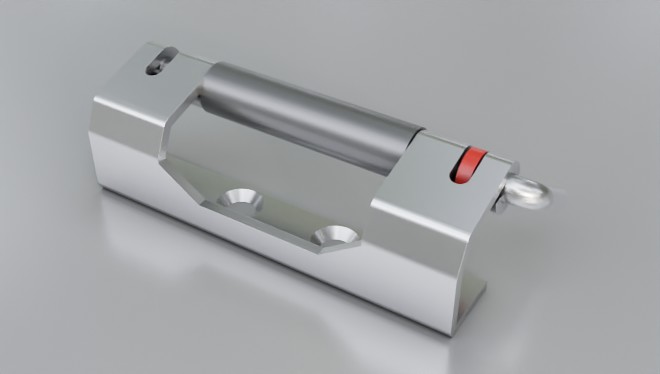

In addition, Enclosure Hardware such as Locks, Hinges, Handles and Gaskets can also be used actually on board trains: on door locking systems, secure control panels and on passenger furniture such as tables and seats. Keeping the trains themselves and their passengers safe is as vital as safely housing the equipment and systems which help to keep the trains running.

Extensive product range

As a recognised specialist in the design, engineering, manufacture and distribution of a wide range of high-quality industrial fastenings and assembly products for the rail sector, our expertise on Enclosure and Locking Hardware – from control and power cabinets to door Locking Systems and secure panels – has positioned us at the leading edge of global supply.

Certainly, the solutions required for a rapidly modernising, increasingly digitalised rail sector are embedded in our extensive enclosure hardware range, including:

We are living in a world where real-time tracking and tracing systems for trains and freight cars, along with the use of drones to monitor trains and ensure the safety of cargo, are likely to become the norm. Only those suppliers who move at the same speed in support of a digitalised rail sector will ensure they are not left behind on the platform.

Published September 2019

Click here to download this article as a PDF