TR Self Clinch Floating Fastener installation

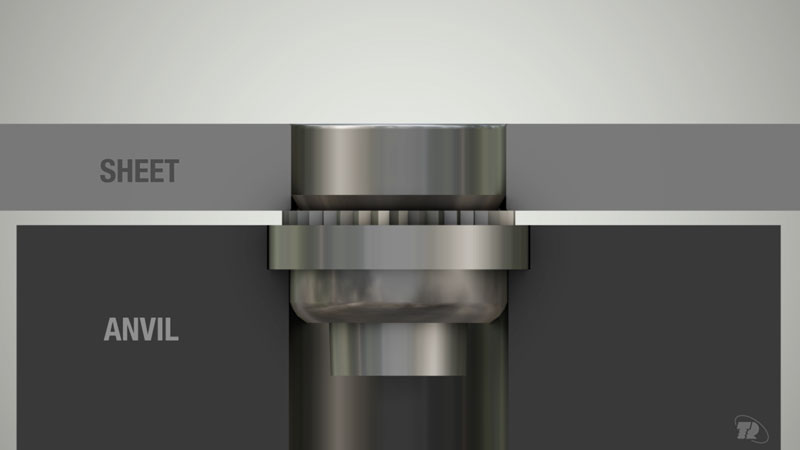

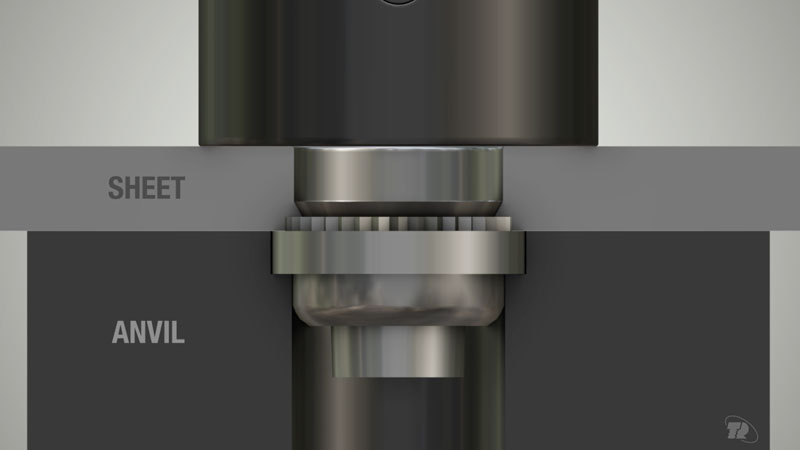

1 Step 1

An anvil with the correct sized hole is fitted to the installation press. The nut is placed in the hole.

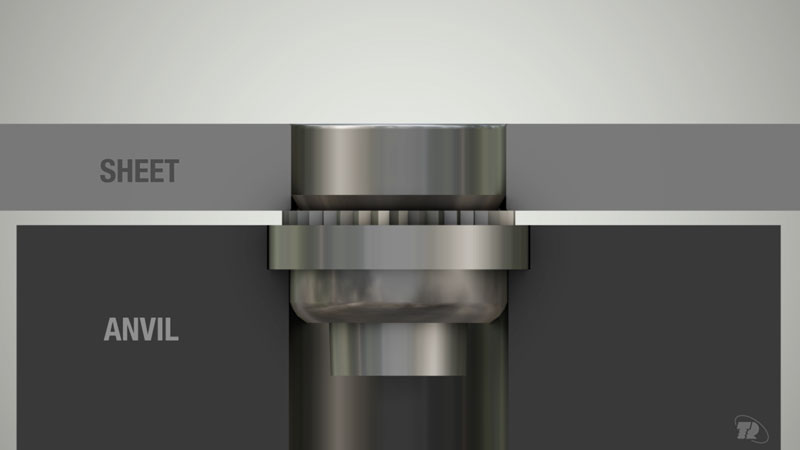

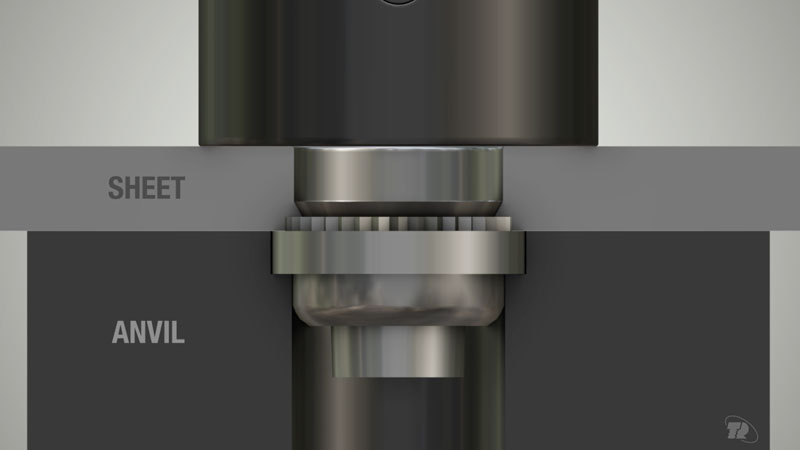

2 Step 2

The sheet with a correctly sized hole is place on the nut so the sheet face rests on the knurls.

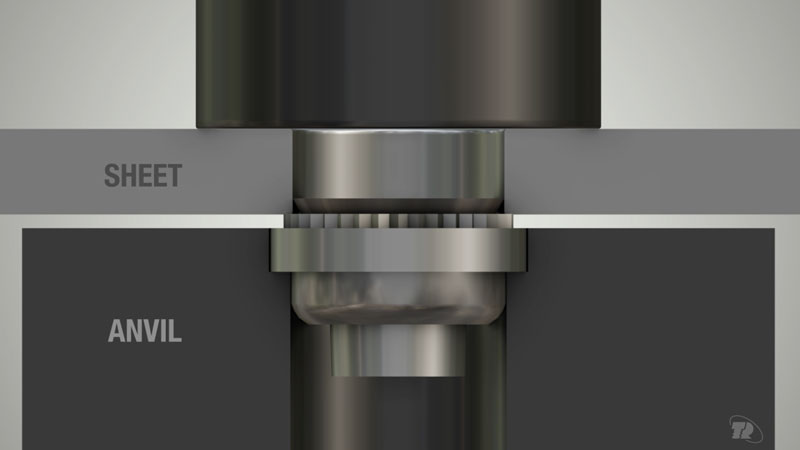

3 Step 3

The punch squeezes the sheet metal onto the nut. The displaced metal flows into the undercut and round the knurls of the nut.

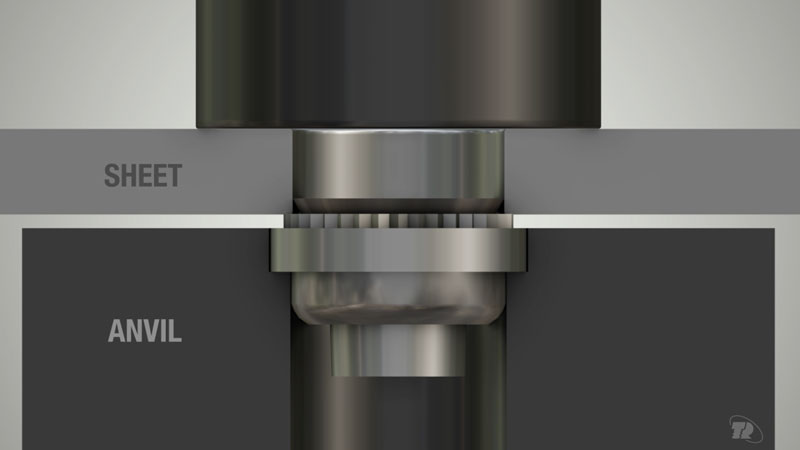

4 Step 4

The nut is fully installed when the sheet sits flush with the anvil face.

Installation animation

Using the table below with reference to the specific size of the fastener, select the correct hole size for the installation of the fastener.

For the best dimensional accuracy and therefore performance, TR recommends that all holes in the sheet metal application be punched.

Note it is essential that the recommended Hole tolerances be observed.

Hole sizes - metric (mm)

| Thread size and pitch | M3 0.5 | M4 0.7 | M5 0.8 | M6 1.0 | |||

|---|---|---|---|---|---|---|---|

| Min sheet thickness | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1.4 |

| Hole size +0.08 -0.00 | 7.4 | 9.4 | 10.31 | 13.1 | |||

| min distance to hole c/l to edge | 7.62 | 8.64 | 9.14 | 11.0 | |||

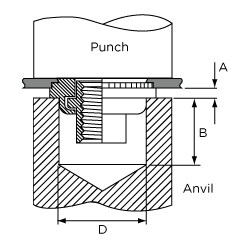

Tooling

|

Thread |

A mm

+/- 0.03

|

B mm

+/- 0.13

|

D mm

+0.05/+0.13

|

|---|---|---|---|---|

| M3 | 1.37 | 6.55 | 7.37 | |

| M4 | 1.37 | 6.55 | 9.28 | |

| M5 | 1.8 | 6.12 | 10.29 | |

| M6 | 2.34 | 5.59 | 12.96 |