Design guidelines for beam joints

According to VDI 2230 guidelines.

| Beam joints | |||

|---|---|---|---|

| Item | Guidelines for design | Disadvantages | Advantages |

| 1 | Preloads: Preloads as high as possible *higher strength grade *exact tightening method *low coefficients of friction | Low preloads | High preloads (choose tightening method with small tightening factor) |

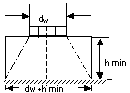

| 2 | Width of beam: Utilise the recommended beam width b=dw =h if possible |

Very narrow joints

|

Width of b=dw =h min beam

|

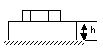

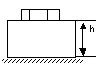

| 3 | Height of the beam: Greater beam heights result in lower additional bolt forces |

Small height of beams

|

Large height of beams

|

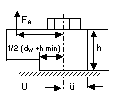

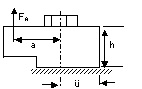

| 4 | Overhang: If possible, design an overhang so that the supporting effect can completely develop. Point U (limit of the bearing surface) is defined by a step. |

Minimal overhang

|

Overhang ü =h

|

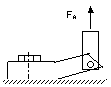

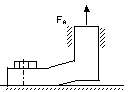

| 5 | Connecting parts: The additional bolt force (difference force) decreases when when the connecting parts force a parallel movement on the beam |

Loose coupling

|

Tight coupling

|