Round Serrated Face Mini Rivet Bush Standoff installation

The Mini Rivet Bush Standoff features a high torque resisting riveting pillar and has the same design characteristics as the Standoff & Hanksert® Rivet Bushes with the additional advantage of being small enough to work in restricted spaces.

Ensure the correct spigot length has been selected for sheet thickness being used. Select the appropriate hole size from the table below for the bush required. Punch the hole diameter into the sheet material.

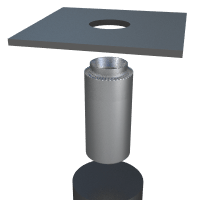

Place the sheet metal on the bush so the spigot protrudes through the hole. If the bush is not seated ‘square’ in the hole, the joint will be imperfect and mating threads will misalign.

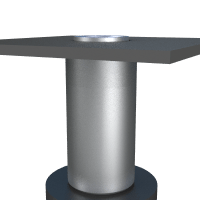

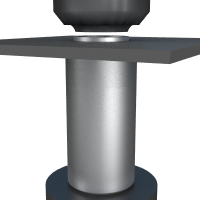

Using a profiled punch, apply only sufficient pressure to ‘peen’ the spigot over into the sheet metal and allow the serrations on the face to embed in the face of the sheet, providing torsional resistance.

Installation animation

|

|

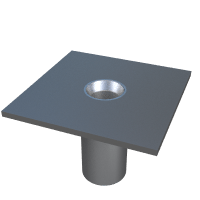

For best torsional and pull-out resistance, the serrated face should be fully embedded in the face of the sheet material and the spigot should be flush with the underside of the sheet after installation. |

Using the table below with reference to the specific size of the Hanksert® Mini Rivet Bush Standoff, select the correct hole size for the installation of the fastener.

For the best dimensional accuracy and therefore performance, TR Fastenings recommends that all holes in the sheet metal application be punched.

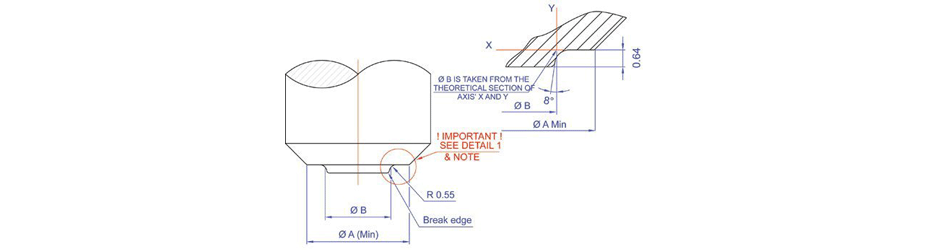

To install the fastener into the punched hole a profiled punch or a ball bearing of a suitable size is required. The profiled punch can be sourced from the TR Fastenings sales team.

Hole sizes - metric (mm)

| Thread form | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M8 | M10 | M12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Recommended hole size +0.05 -0.00mm | 3.50 | 4.19 | 4.19 | 5.41 | 5.41 | 6.40 | 7.70 | 9.70 | 12.70 | 15.87 | |

Hole sizes - inches

| Thread form | BSW/F | - | - | 1/8" | - | 5/32" | 3/16" | 1/4" | 5/16" | 3/8" | 1/2" |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BA | 8 | - | 6.5 | 4 | 3 | 2 | 0 | - | - | - | |

| UNC | 2 | - | 4 | 6 | 8 | 10 | 1/4" | 5/16" | 3/8" | 1/2" | |

| UNF | 2 | - | 4 | 6 | 8 | 10 | 1/4" | 5/16" | 3/8" | 1/2" | |

| Recommended hole size +0.002 -0.000™ | .138 | .165 | .165 | .213 | .213 | .252 | .303 | .382 | .500 | .625 | |

Tooling

Detail 1 - Oil hardening steel 665 M17 (EN34)

Note: 760°C - 780°C oil quench temper 150°C - 200°C

| Punch dimensions | ||

|---|---|---|

| Thread size | A | B |

| M2 | 5.00 | 3.05 |

| M2.5/M3 | 9.05 | 3.68 |

| M3.5/M4 | 10.50 | 4.90 |

| M5 | 12.00 | 5.87 |

| M6 | 14.00 | 7.09 |

| M8 | 16.30 | 8.89 |

| M10 | 21.90 | 11.89 |

| M12 | 25.40 | 15.04 |