The TR EPW thread-forming screw revolutionises the fastening process for thin sheet metal by cutting assembly time and cost - 12.09.2024

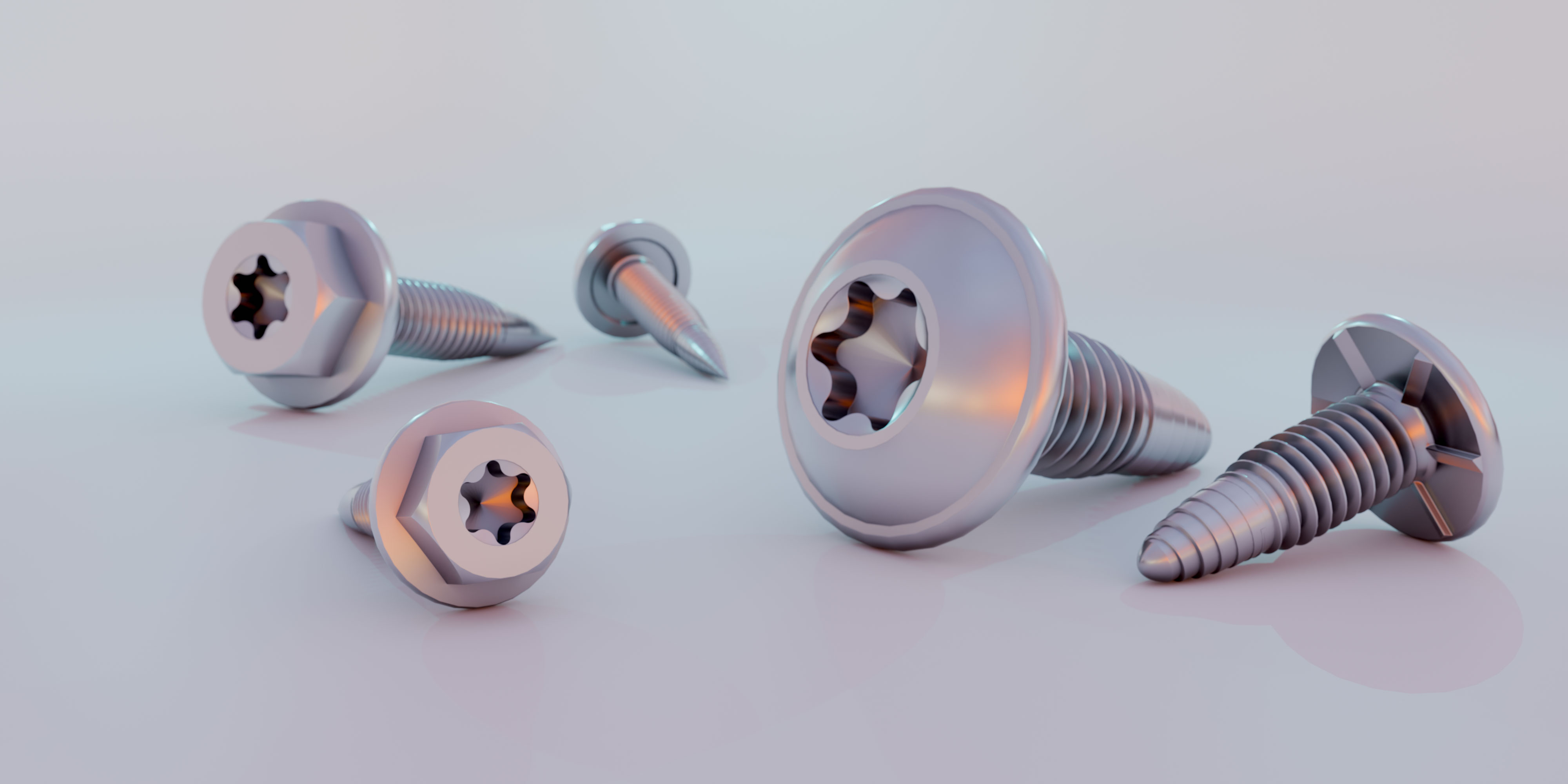

TR Fastenings, part of the Trifast plc group of companies, has relaunched its patented EPW self-extruding thread-forming screw, engineered to significantly cut assembly time and cost. A revolutionary fastening solution, proudly designed and manufactured in Europe, the TR EPW creates its own internal thread in thin sheet metal, and suits the HVAC, automotive, electronics, medical and telecoms industries

Why is the TR EPW a game changer?

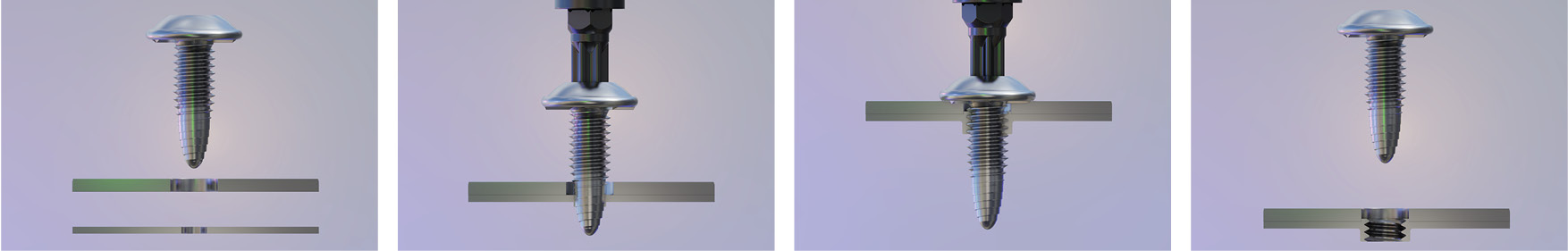

Unlike traditional flow drill products, the EPW screw can be easily installed by hand with a cordless drill making it extremely convenient and versatile. It works by aligning to the pilot hole in the sheet metal, forming an extruded collar and creating a robust thread profile before tightening and clamping securely, all in one easy step.

Other key features:

- Can be installed manually and via robotic systems

- Easily removed and fully reusable for a strong, long-lasting joint

- Excellent vibration resistance to keep the assembly secure

- High radial compression on the screw shank for a superior hold

- Suitable for electrical earth connections

- Lightweight, practical and strong

- Manufactured in house in Europe

Manufactured in Europe by TR for global markets

Designed, developed and patented by TR, the EPW is an innovative high strength fastener manufactured in TR’s own factory in Italy and available to global markets in a range of materials, sizes and head styles. Surface coatings include standard zinc plating, high-corrosion zinc nickel and organic zinc flake. Effective in use with thin sheet metal, the EPW creates fixtures that are easy to disassemble, enabling users to recycle or reuse parts as and when required.

The EPW offers cost-effective solutions to users, thanks to its versatility of use, ease of installation and its reliability. It can be used for a variety of materials, including steel (0.4-1mm thick) and aluminium (0.4-1.5mm thick), complementing an already comprehensive product range that includes self-clinch fasteners, blind rivets, welding products and more.

Enrico DeAngelis, Research & Development, TR Italy commented: “The EPW screw represents a significant commitment on our part to provide the finest possible product designs allied to the very best in quality, functionality and versatility. Relaunching this fastener now is perfect timing as customers are coming to us for more cost-effective solutions for thin sheet metal. The success that we feel this product will bring is due to a culmination of factors, including of course the investment that TR has made.”

Published 12.09.2024

Click here to download this article as a PDF