Design guidelines for cylindrical joints

According to VDI 2230 guidelines.

| Cylindrical joints | |||

|---|---|---|---|

| Item | Guidelines for design | Disadvantages | Advantages |

| 1 | Preloads: Preloads as high as possible *Higher strength grade *Exact tightening method *Low coefficients of friction | Low preloads | High preloads (choose tightening method with small tightening factor) |

| 2 | Eccentricity of the bolt: Aim to obtain the lowest possible eccentricity of bolt positions |

Large eccentricity

|

Minimal eccentricity

|

| 3 | Eccentricity of the load introduction: Minimal eccentricity causes smaller additional bolt forces |

Large eccentricity

|

Minimal eccentricity

|

| 4 | Height of load introduction: Introduce the load as close to the interface as possible |

Load introduction of the upper region

|

Load introduction in the vicinity of the interface

|

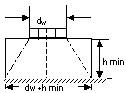

| 5 | Rigidity bolt - cylinder: The resilience of the bolt should be as high as possible, compared to the resilience of the clamped part. If need be, with reduced body diameter bolts. |

Thin small cylinder (for given nominal diameter)

|

G = dW+hmin

|