Estimating bolt diameters

| Load in N | Nominal Dia. In mm | ||

|---|---|---|---|

| Strength grade | |||

| 12.9 | 10.9 | 8.8 | |

| 250 | - | - | - |

| 400 | - | - | - |

| 630 | - | - | - |

| 1000 | - | - | - |

| 1600 | 3 | 3 | 3 |

| 2500 | 3 | 3 | 4 |

| 4000 | 4 | 4 | 5 |

| 6300 | 4 | 5 | 5 |

| 10000 | 5 | 6 | 8 |

| 16000 | 6 | 8 | 8 |

| 25000 | 8 | 10 | 10 |

| 40000 | 10 | 12 | 14 |

| 63000 | 12 | 14 | 16 |

| 100000 | 16 | 16 | 20 |

| 160000 | 20 | 20 | 24 |

| 250000 | 24 | 27 | 30 |

| 400000 | 30 | 36 | - |

| 630000 | 36 | - | - |

A. Select the lowest load from column 1 which is higher than the working load FA. (FA = Axial Force; a calculated working load in the bolt axis or the components of a given calculated working load) acting on the bolted joints.

B. The required minimum initial clamp load FMmin (FMmin = Minimum initial clamp load established at FMmax as a result of lack of precision in the tightening technique) is determined by increasing this column 1 load by further steps as shown below:

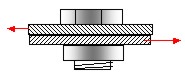

Static or dynamic transfer loads

4 Steps

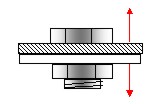

Dynamic or eccentrically applied loads

2 Steps

2 steps for tightening the bolt using a simple tightening spindle which has been set by the retightening torque.

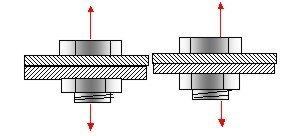

Dynamic and concentrically applied or static and eccentrically applied working loads

1 Step

1 step for tightening using a torque wrench or precision spindle adjusted and controlled by means of dynamic torque measurement or elongation measurement of the bolt.

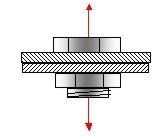

Static and concentrically applied axial loads

0 Steps

0 steps for tightening by means of angle control in the plastic range or by means of computer controlled yield load monitoring.

C. The required maximum initial clamping load FMmax is determined by increasing this load FMmin by:

2 steps for tightening the bolt using a simple tightening spindle which has been set by the retightening torque, or

1 step for tightening using a torque wrench or precision spindle adjusted and controlled by means of dynamic torque measurement or elongation measurement of the bolt, or

0 steps for tightening by means of angle control in the plastic range or by means of computer controlled yield load monitoring.

D. Next to the number found, columns 2 to 4 give the required bolt dimensions in mm for the selected bolt strength grade.

Example

A joint is dynamically and eccentrically loaded by the axial load FA = 8500N. A bolt strength grade 12.9 is to be assembled using a torque wrench.

A. 10,000N is the next largest load to FA in column 1

B. 2 steps for eccentric and dynamic axial loading give FMmin = 25,000N

C. 1 step for tightening using a torque wrench gives FMmax = 40,000N

D. For FMmax = 40,000N, we find in column 2 (Strength Grade 12.9 ) ; M10