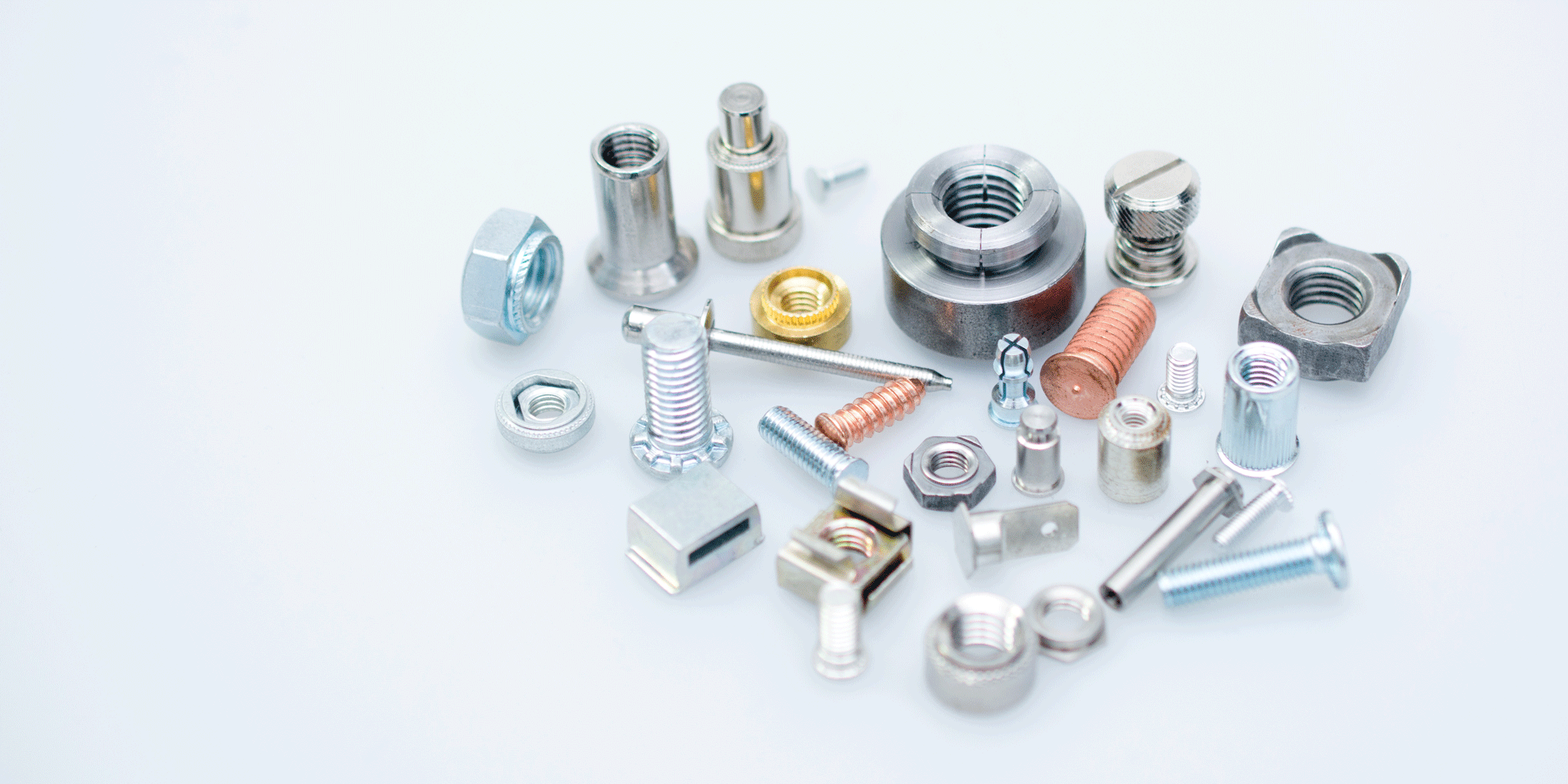

Sheet Metal Products: Self Clinching fastener solutions for pressing installation

TR Fastenings manufactures and distributes a wide spectrum of sheet metal fastening products that are pressed into pre-punched holes. These include our own branded Self Clinch fasteners, Hank® Rivet Bushes, and K-Series® Nuts. TR’s sheet metal clinching products provide strong load bearing threads in sheet metal of differing thicknesses

Installation process overview

Self Clinch fasteners are designed for installation when both sides of the sheet metal are accessible using a parallel squeezing force, delivered by pneumatic press.

The fast and simple pressing installation process using Self Clinch Studs, Nuts, Standoffs or Panel Fasteners creates mutual self deformation between the mating part and the sheet metal fixing. The clinch fastener becomes a permanent part of the sheet metal panel delivering a hugely reliable and strong fixing.

Products

We hold an extensive range of our own branded Self Clinch products in stock, with access to either our own manufacturers or reliable distributor networks we can also deliver bespoke or product variants at speed.

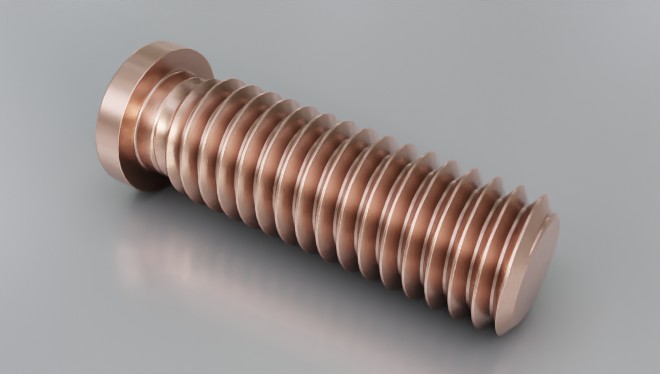

Self Clinch Fasteners

Designed to offer a permanent female or male thread in sheet metal across a wide range of critical applications, our own-branded Self Clinch products come in a range of shapes and sizes, including Threaded Clinch Studs, Clinch Nuts, Standoffs, Panel Fasteners and Pins. All have a high pull-out and torque tolerance and come in a wide variety of materials and plated finishes.

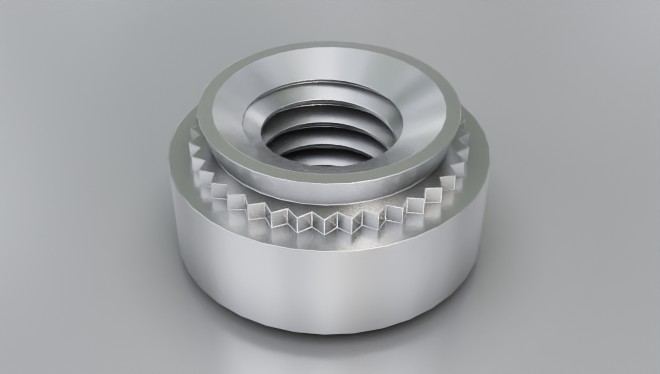

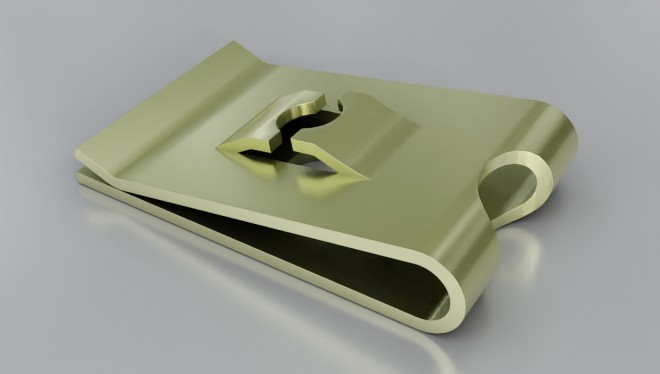

Hank® Rivet Bushes

Our comprehensive range of Hank® Rivet Bushes are designed to add load bearing female threads in thin sheet metal. Offering the best torsional and pull-out resistance, our range of Rivet Bush products include round serrated face, round serrated spigot, hexagon, standoffs, mini round, Tank and Swage.

Our Hank® Rivet Bushes are manufactured in a variety of materials and finishes.

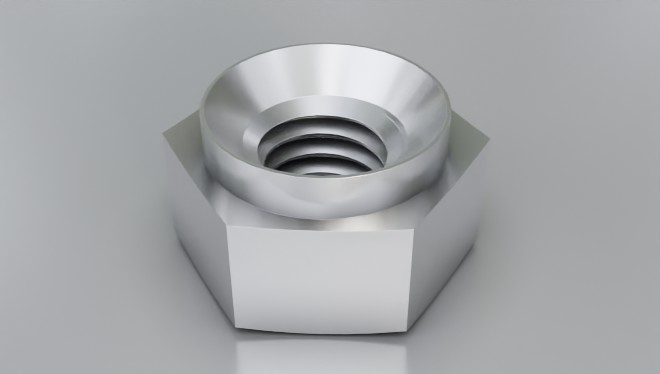

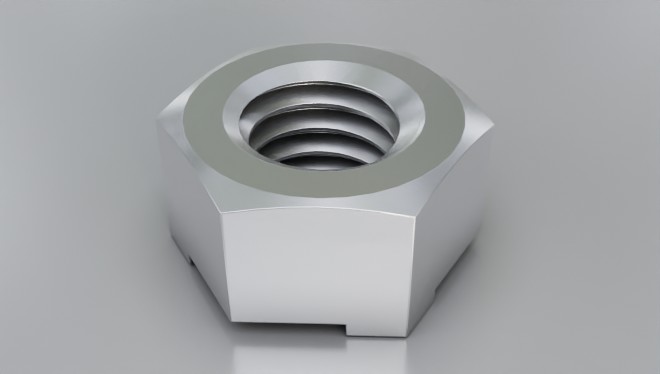

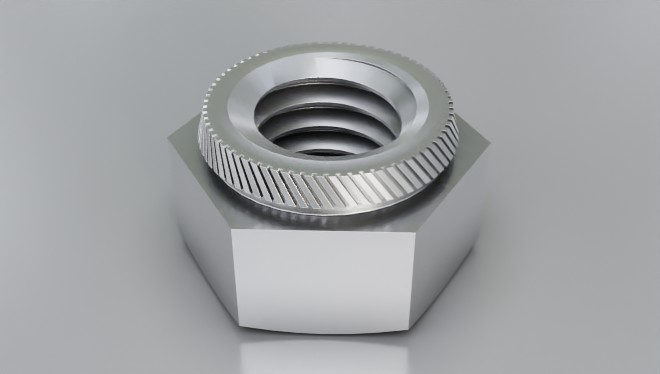

K-Series® Nuts

Our K-Series® Nuts are versatile products providing a strong and permanent female thread for sheet metal and some plastic applications too thin to be tapped by usual methods. Our K-Series® Standard and Thin Nuts can be installed using a standard press. Once fixed, our K-Series® Nuts offer a strong fixing and permanent thread with a high prevailing torque and pull-out resistance.

Did you know?

The Self Clinch range of products were invented in 1942, whilst the Hank® Rivet Bush dates back to 1928.